À quoi sert une presse mécanique ?

2025-12-20 17:00

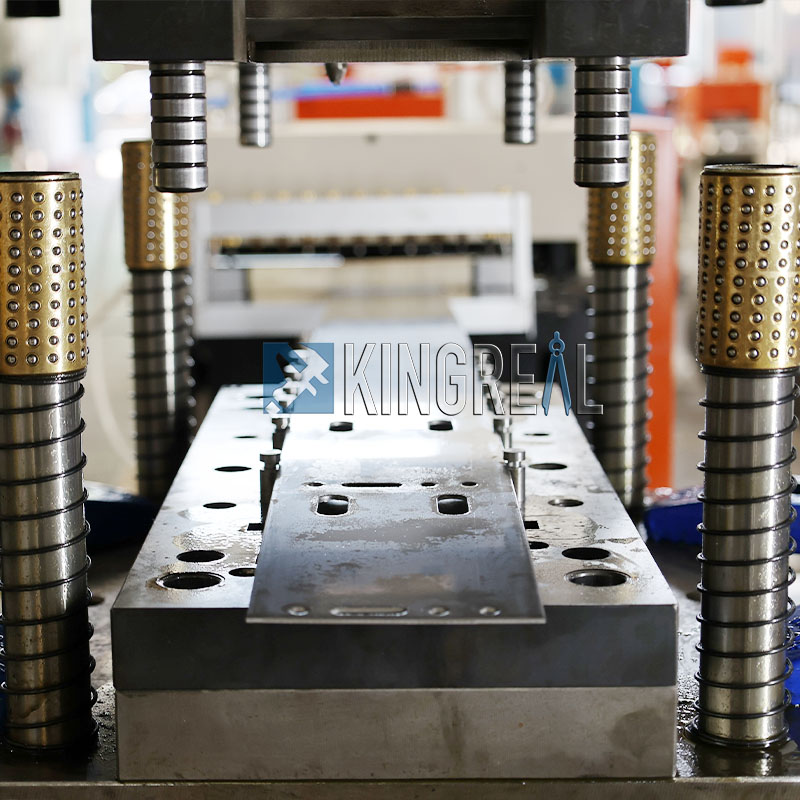

Dans la fabrication moderne,presses à dynamoLes presses mécaniques automatiques sont largement utilisées dans de nombreux secteurs industriels. Elles utilisent des matrices progressives pour réaliser une série d'opérations sur les matériaux métalliques, telles que le poinçonnage, le frappage, le découpage, le pliage et le bordage, afin de produire des pièces métalliques de formes et de dimensions variées. Ces pièces sont couramment utilisées dans les structures métalliques, les systèmes de rayonnage et la fabrication automobile, entre autres. On peut affirmer que presque tous les systèmes et produits de notre quotidien nécessitent des pièces métalliques produites par des presses mécaniques pour leur fixation et leur assemblage.

Le rôle des presses mécaniques

| presses mécaniques automatiques Elles servent principalement à transformer les matériaux métalliques en diverses formes spécifiques. Elles combinent généralement plusieurs procédés, ce qui témoigne de leur polyvalence dans le processus de production. Les presses mécaniques sont présentes dans presque tous les secteurs : électroménager, véhicules, éléments architecturaux, etc. Grâce à ces presses automatiques, les producteurs peuvent fabriquer rapidement et avec précision de grandes quantités de composants métalliques, répondant ainsi à de nombreux besoins du marché. |

Où les presses mécaniques peuvent-elles être utilisées ?

1. Presses mécaniques dans l'industrie des structures métalliques

Dans l'industrie des structures métalliques, les presses mécaniques sont utilisées pour fabriquer diverses plaques de connexion, cornières et autres composants essentiels. Ces composants, généralement en acier à haute résistance, sont formés et usinés à l'aide de presses mécaniques automatiques afin de répondre à différentes exigences de charge. Les produits emboutis améliorent non seulement la stabilité de la structure, mais réduisent également le nombre de points de soudure, ce qui diminue les coûts d'ingénierie.

2. Presses mécaniques dans les systèmes de rayonnages

La construction des systèmes d'étagères repose également sur le support depresses mécaniques automatiquesLes cadres de support, les poutres et les éléments de liaison des rayonnages nécessitent généralement un emboutissage pour obtenir des dimensions précises et une bonne capacité de charge. Les pièces produites à l'aide de presses mécaniques permettent d'améliorer l'efficacité des systèmes de rayonnage et d'optimiser les fonctions d'entreposage et de logistique.

3. Presses mécaniques dans la fabrication automobile

Les presses mécaniques automatiques sont également essentielles dans le secteur de la fabrication automobile. L'emboutissage permet de produire de nombreux composants automobiles, tels que la carrosserie, le châssis, les supports de fixation et les éléments intérieurs. Pour garantir la sécurité et la durabilité des véhicules, ces composants métalliques doivent présenter une précision et une régularité de fabrication exceptionnelles. Parallèlement, l'excellente productivité des presses mécaniques permet de réduire les coûts de production et d'accélérer la mise sur le marché.

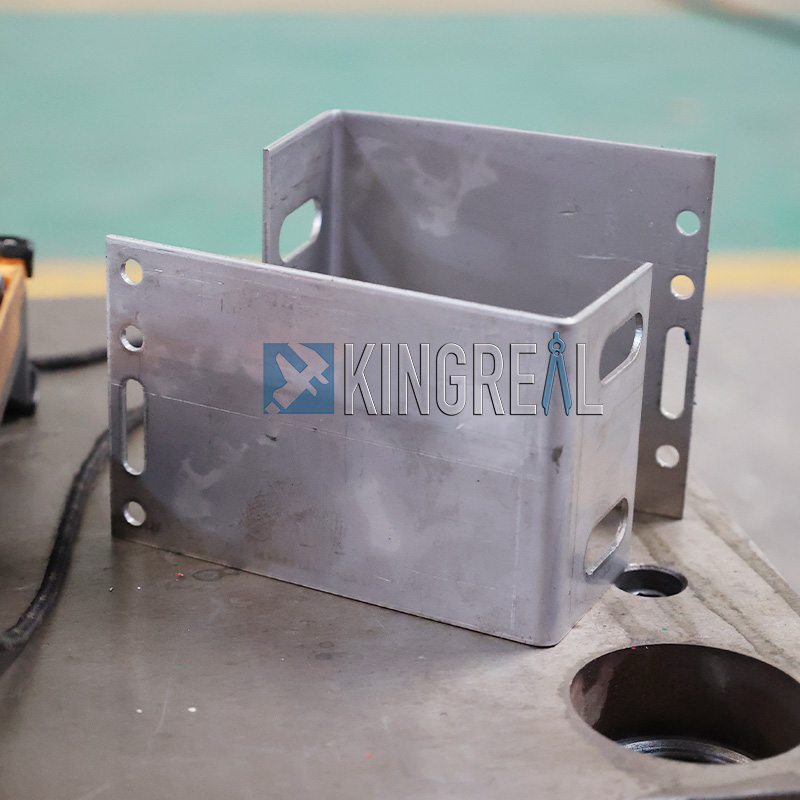

4. Presses mécaniques automatiques dans la fabrication de produits électroniques

Dans les produits électroniques modernes, de nombreux boîtiers, socles et connecteurs internes métalliques sont également fabriqués à l'aide de presses à emboutir. La haute précision et les formes complexes souvent requises pour les composants métalliques des appareils électroniques grand public, tels que les téléphones portables et les ordinateurs, se prêtent parfaitement à la technologie d'emboutissage.

Quels matériaux sont couramment utilisés dans les presses mécaniques automatiques ?

presses à dynamopeut traiter divers matériaux métalliques. Les alliages couramment utilisés comprennent :

-Acier : Grâce à sa bonne résistance et à son usinabilité, l’acier est largement utilisé dans l’emboutissage. Il convient à diverses exigences de charge et possède une capacité de charge extrêmement élevée.

-Acier inoxydable : L’acier inoxydable convient aux objets nécessitant à la fois beauté et durabilité, notamment les éléments décoratifs architecturaux et les équipements de cuisine, grâce à son excellente résistance à la corrosion et à son aspect raffiné.

-Cuivre : Le cuivre possède une excellente conductivité électrique et est souvent utilisé dans l'estampage de produits électroniques et de composants électriques.

Aluminium et laiton : Ces deux matériaux permettent de fabriquer des éléments structurels et ornementaux légers, tout en s’allégeant eux-mêmes le poids du matériau. Grâce à leur résistance à l’oxydation, les alliages d’aluminium sont omniprésents.

Exigences relatives aux presses à commande numérique personnalisées

Sur le marché moderne, la standardisationpresse mécanique automatiqueIl est souvent impossible de répondre à tous les besoins des clients. C'est pourquoi les presses mécaniques KINGREAL CEILING MACHINE peuvent être personnalisées pour répondre précisément à vos exigences. Les experts de KINGREAL CEILING MACHINERY analyseront attentivement vos besoins de production et concevront la presse mécanique automatique la plus adaptée.

Flexibilité de conception : KINGREAL CEILING MACHINERY peut adapter la configuration de la machine, y compris la conception des moules et les processus de production, aux besoins spécifiques des clients afin de maximiser l’efficacité de la production.

Stabilité et fiabilité : Les presses à commande numérique personnalisées subissent des tests rigoureux afin de garantir un fonctionnement stable lors d'une production à long terme et de réduire les taux de pannes mécaniques.

Maintenance des presses mécaniques automatiques

Un entretien quotidien est essentiel si l'on veut garantir quemachine de presse à puissanceest en bon état de fonctionnement. Un entretien efficace permet non seulement d'allonger la durée de vie de la presse mécanique automatique, mais aussi d'accroître sa productivité. L'entretien comprend principalement :

Lubrification : La lubrification régulière des pièces mobiles de la presse mécanique automatique permet de réduire l'usure et d'assurer un bon fonctionnement.

Remplacement des pièces usées : Certains composants essentiels peuvent s’user après une utilisation prolongée et doivent être remplacés à temps afin de ne pas nuire à la productivité. Nettoyage : Nettoyez régulièrement les copeaux de métal et la poussière à l’intérieur de la presse afin d’éviter tout problème de fonctionnement et de maintenir la propreté de l’équipement.

Inspection régulière : Procéder à des inspections régulières du système électrique, du système hydraulique et des dispositifs de sécurité de la presse mécanique automatique afin d'assurer leur bon fonctionnement.

Les différents modèles de presses mécaniques et leurs usages nécessitent des plans et des méthodes d'entretien spécifiques. Les fabricants fournissent généralement des manuels d'entretien détaillés afin de garantir l'efficacité des opérations de maintenance.

Contactez KINGREAL CEILING MACHINERY pour obtenir des informations supplémentaires sur lepresse mécanique automatique.

Obtenez le dernier prix? Nous répondrons dès que possible (dans les 12 heures)