Comment percer un micro trou avec une machine de perforation de tôle ?

2025-03-31 17:00

Punching technology plays an important role in modern manufacturing, especially in areas that require precision processing. As an efficient processing equipment, coil perforation line is widely used in the processing of metal materials.

This article will explore the common punching apertures of metal sheet coil perforation lines on the market, the application areas of micro perforation, and how KINGREAL CEILING MACHINERY provides high-precision micro perforation solutions.

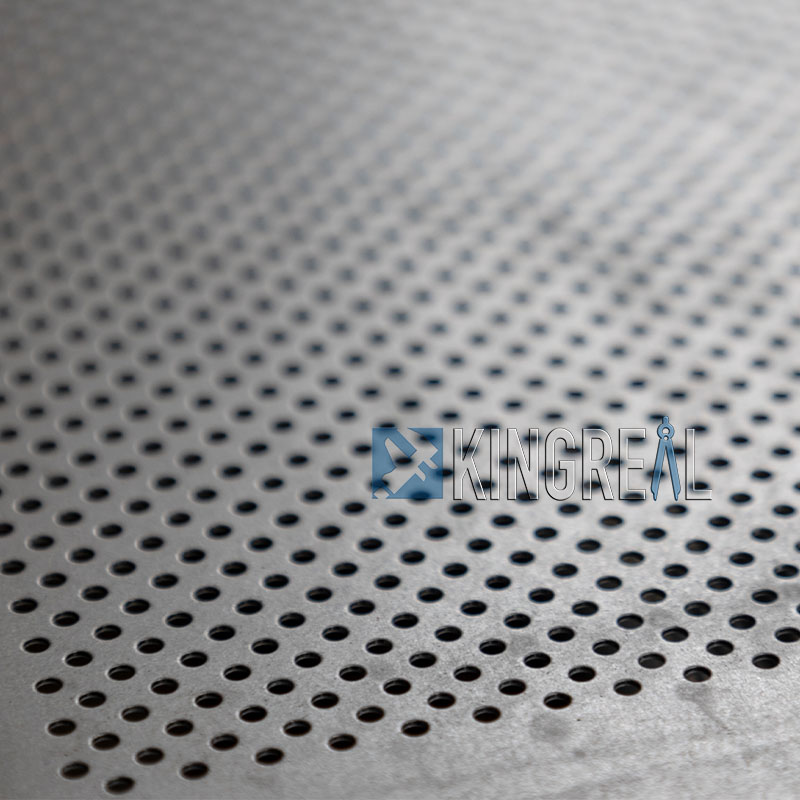

Common punching apertures of coil perforation lines on the market

In the current market, the common punching apertures of metal sheet coil perforation lines are mainly concentrated in 1.8mm and 2.5mm. These apertures are suitable for a variety of industrial applications, especially in the electronics, automotive, construction and other industries, and have a broad application base.

● Application of 1.8mm aperture

Coil to coil perforated making machines with 1.8mm aperture are mainly used for the processing of circuit boards, the production of metal meshes, and the punching of other light materials. This aperture can meet the assembly needs of most small electronic components and is suitable for many fields such as mobile phones, computers, and household appliances. In these products, precise apertures are essential for the accurate installation and functional realization of components.

● Application of 2.5mm aperture

In contrast, the 2.5mm aperture coil to coil perforated making machine mainly serves larger industrial needs, such as punching of automobile bodies, processing of building materials, etc. This aperture punching can form larger holes in metal sheets to meet the needs of ventilation, drainage and other functions, and is widely used in construction, transportation and other industries.

Although 1.8mm and 2.5mm are common punching apertures on the market, with the development of science and technology and changes in market demand, the demand for micro-hole processing is increasing, especially in high-precision and high-density application scenarios.

Application fields of micro perforation

Micro perforation refers to punching processing with an aperture less than 1.8mm, usually between 0.1mm and 1.5mm. The application field of micro-holes is very wide, covering many high-tech industries. The following are some of the main application areas:

1. Electronics industry

In the electronics industry, micro perforation is widely used in the manufacture of circuit boards and the production of connectors. Micro-holes can provide higher wiring density and help realize more miniaturized electronic products. With the advancement of technology, devices such as smartphones and tablets have increasingly stringent requirements for the aperture of circuit boards, and micro perforation technology has therefore become popular.

2. Medical devices

In the medical industry, micro-holes are used in the manufacture of various medical devices, such as syringes, catheters, and other precision instruments. Precise control of micro perforations can ensure the safety and effectiveness of the equipment. In addition, the application of micro-holes in biosensors and drug delivery systems is becoming more and more common.

3. Automobile manufacturing

The demand for coil to coil perforated making machine in the automotive industry is also growing, especially in the context of lightweight and energy-saving design. Micro-holes can be used to reduce the weight and increase the strength of automotive parts, while also meeting the needs of ventilation and cooling, and improving the overall performance of the car.

4. Aerospace

In the aerospace field, coil to coil perforated making machine is used to manufacture lightweight and high-strength materials such as composites and alloys. The application of micro-holes can significantly reduce the weight of aircraft and spacecraft, improve fuel efficiency and safety.

5. Textile industry

Micro-holes are also used in the textile industry, especially in the production of functional fabrics. These micro-holes can provide breathability and comfort, meeting the functional needs of modern consumers for clothing.

KINGREAL CEILING MACHINERY provides coil perforation line for micro perforation

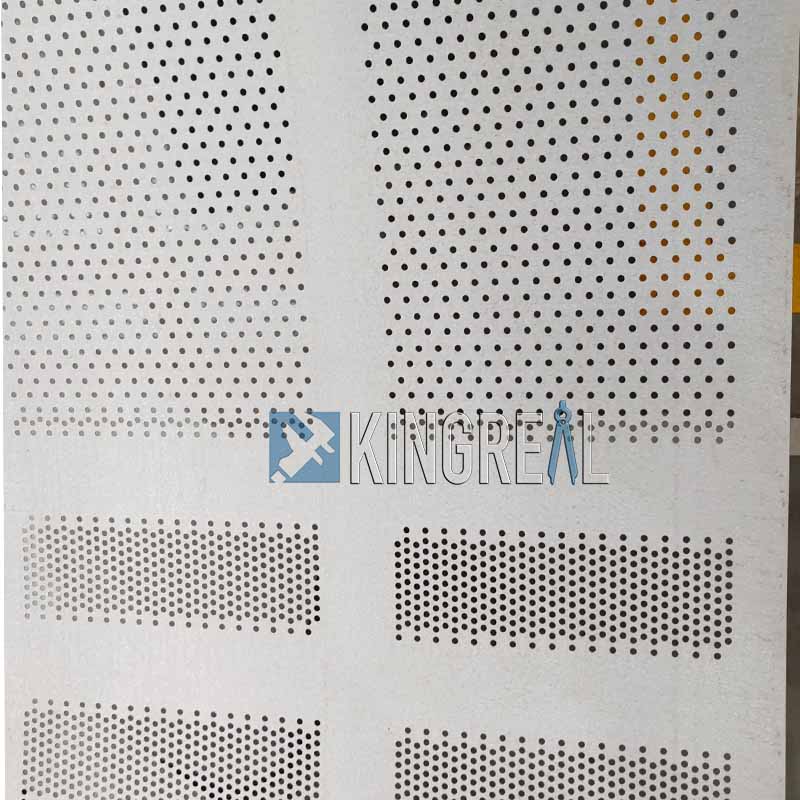

As an industry-leading metal sheet coil perforation line manufacturer, KINGREAL CEILING MACHINERY is committed to providing high-precision micro perforation solutions. KINGREAL CEILING MACHINERY has helped Greek customers design a coil to coil perforated making machine that can punch out micro perforations with a diameter of 1.0mm. The punching die process required by this technology is relatively difficult.

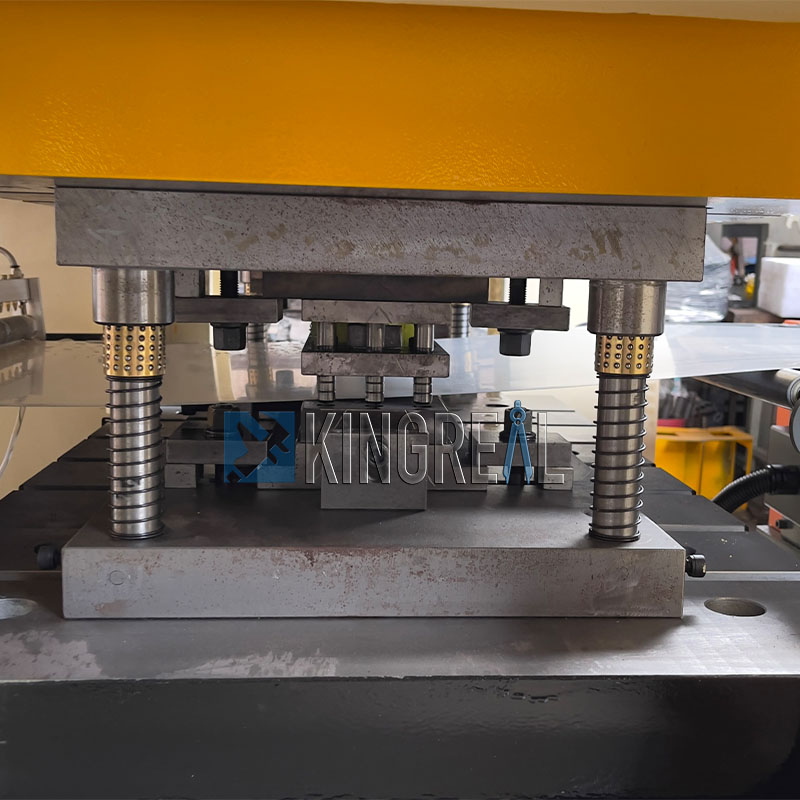

1. Advanced technical support

KINGREAL CEILING MACHINERY's metal sheet coil perforation line uses advanced servo drive technology, which can achieve high-speed punching while ensuring high precision. The application of this technology enables us to maintain stable pressure and speed during the punching process to ensure the quality and consistency of micro-holes.

2. Precision die design

The design of the punching die is the key to the success of micro perforation. KINGREAL CEILING MACHINERY's engineering team has rich experience in die design and can design punching dies suitable for different materials and aperture requirements according to the specific needs of customers. Through precise mold processing, we ensure that every micro hole can meet the design standards.

3. Strict quality control

KINGREAL CEILING MACHINERY applique un système de contrôle qualité strict tout au long de son processus de production. Chaque machine de fabrication de plaques perforées bobine par bobine est soumise à des tests rigoureux avant de quitter l'usine afin de garantir qu'elle atteigne les performances attendues en production. De plus, nous offrons un service après-vente complet pour garantir à nos clients une assistance et des solutions rapides pendant l'utilisation.

4. Service personnalisé

Afin de répondre aux besoins des différentes industries et clients, KINGREAL CEILING MACHINERY fournit également desligne de perforation de bobines de tôleSolutions de fabrication. Qu'il s'agisse de l'ouverture, de la profondeur ou du choix du matériau de la microperforation, nous pouvons l'adapter aux exigences spécifiques du client et fournir la meilleure solution de fabrication de ligne de perforation de bobines de tôle.

Obtenez le dernier prix? Nous répondrons dès que possible (dans les 12 heures)